Aluminum Steel Cut to Length Line Coil Leveling Cutting to Length Machine

Basic Info.

| Model NO. | Coil Cut To Length |

| Rhythm | Flow Production Line |

| Production Scope | Product Line |

| After-sales Service | 2years |

| Production Width | 16mm |

| Colour | Yellow |

| Production Thickness | 1-4mm |

| Power | 30kw |

| Transport Package | Standard Export Package |

| Specification | 1600x4 |

| Trademark | KEFA |

| Origin | Cangzhou |

| HS Code | 845522 |

| Production Capacity | 500pic/Year |

Product Description

Cut to Length Line

Cut to Length Lines are Used for Cutting variety of Metal Coils with Shear in to desired Dimensions.

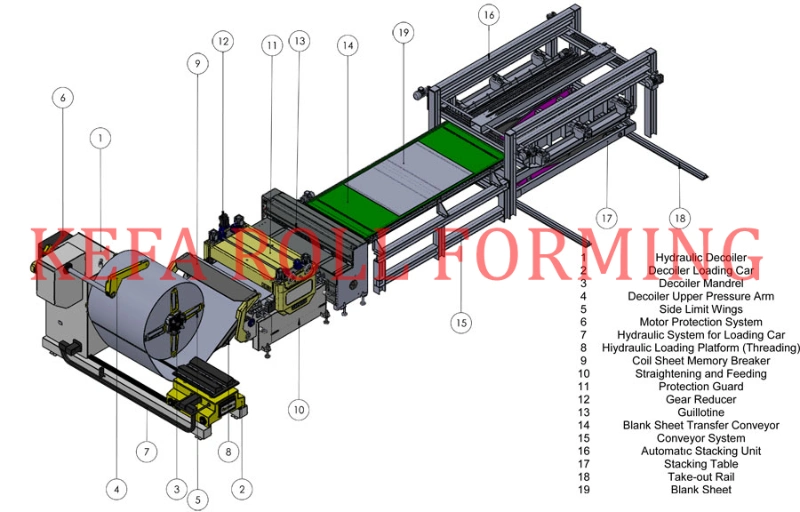

KEFA Cut to Length Lines are Consist of the Decoiler, Servo Feeder with Straightener, Shear and Automated Stacking Units. With all this equipment, our Line is a feature-complete Turnkey Project for our Customers.

| -Easy Operation and Maintenance with High Level Automation |

| -Hydraulic Decoiler With A Loading Car for Easy Coil Loading |

| -Straightener with Multiple Rollers For The Maximum Surface Quality |

| -Accurate Surface Treatment with High-Quality Rollers |

| -High-Quality Cuts with Minimum Burr/Scarps |

| -Automated Stacking System with High Accuracy |

| -High Capacity Lines with Minimum Area Needs |

| -Low Cost, High Quality, Maximum Efficiency |

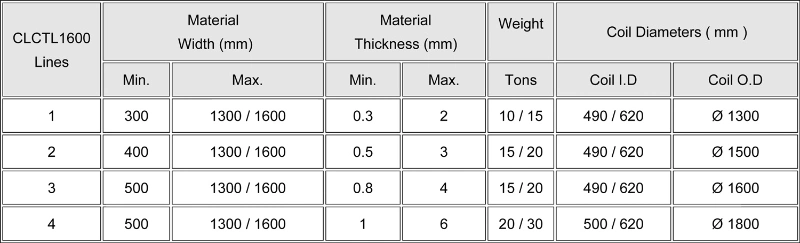

KEFA's CTL Line's working ranges are 0.4 - 3 mm for Thicknesses and up to 1600 mm for Widths.

Botou Kefa Roll Forming Machine Co., Ltd. is a manufacturer specializing in custom cold roll forming equipment and automatic production lines. We can manufacture hundred types roll forming machines,like Door frame machine,K type long span arching roof machine,automobile profile machine,Container house series machine,Steel silo series machine,Chicken cage series machine,Fence series machine,shelf series machine,highway guardrail series machine,coil leveling machine and all kinds of construction profiles. Engineers and technicians are rich in experience of designing,developing and manufacturing of machines to provide customers with customized designs. We pay close attention to new trend of technologies.Our products are sold to many countries and regions around the world, and we have established long-term cooperative relationships with customers.

1. Quality Control

A. Every parts of machine is examed carefully without any omit.

B. Welcome to our factory to check machine2. Installation & Training

A. We supply video to teach buyer how to install and operate machine

B. Welcome customers come to our factory, we are glad to teach you face to face.

C. Our technicians could come to customers' factory to install machine3. After-sale service

A. One year warranty for parts and shipment of parts is free.

B. 24hours*365 days technical support online.

FAQ1.How to maintain the machine?Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.3.How many workers to operate the machine?

A:Only 1-2 workers.4. How to visit your company?a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.5. What can you do if the machine broken?Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,2) Please visit company and test machine if convenient.